Eco-friendly planting solutions

Seaweed nanocellulose hydrogels, a high-value component found in cosmetics and wound care, are now making waves in the forestry sector. They’re being tested as eco-friendly alternatives to petroleum-based polymers, potentially boosting plant health and extending the planting season when using mechanised tree planting systems.

Hydrogels are celebrated for their exceptional water-absorbing prowess, capable of retaining water up to 100 times their own weight. When hydrated, they transform into a gel-like substance, gradually releasing stored water as needed.

Traditionally, the world’s nanocellulose supply relies on wood pulp treated with harsh chemicals. However, a collaboration in 2017 between Scion – an expert in wood pulping, and AgriSea – a Māori owned family business based in Paeroa, sought an alternative approach to the sustainable production of this versatile polymer using seaweed.

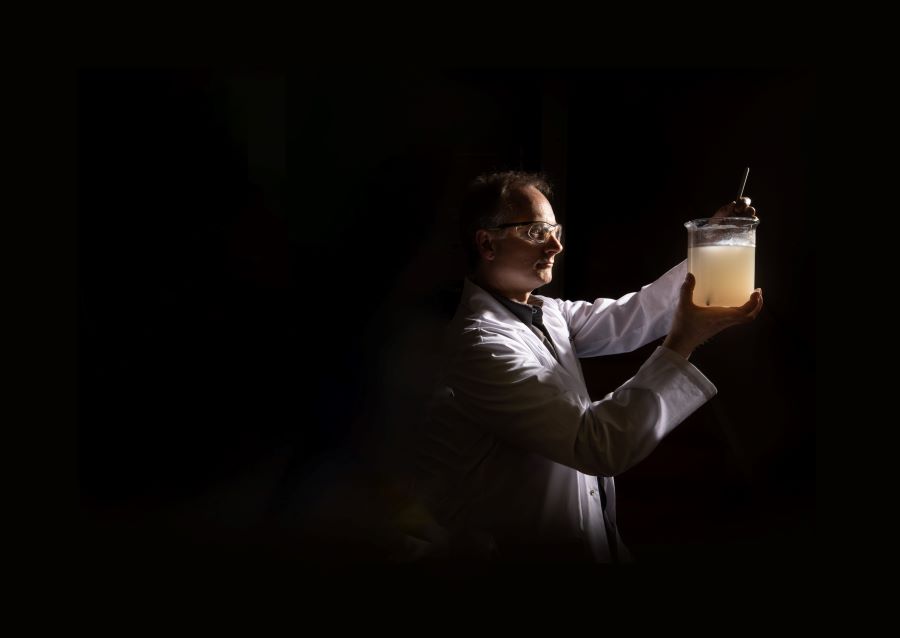

Dr Stefan Hill, Scion’s portfolio leader for High Value Biorefineries, says extracting nanocellulose from seaweed complements AgriSea’s core business of providing bio-stimulants to farmers and growers.

“This initiative aligns perfectly with the principles of a circular economy, where waste becomes an input for another process, leaving us with nothing but CO₂ and water.

Environmental stewardship is paramount to AgriSea, reflecting the commitment to caring for the whenua (land) and natural resources central to their mission. For Scion, the collaboration exemplifies research aimed at developing renewable bio-based products to combat climate change.

Seaweed-based hydrogels are now undergoing trials to determine their potential to improve seedling establishment and growth in forestry. Their capability to extend the planting season beyond winter’s boundaries, courtesy of mechanised planting systems, could prove critical in helping the forestry sector adapt to New Zealand’s ever-changing climate patterns.

This initiative aligns perfectly with the principles of a circular economy - Dr Stefan Hill

Hydrogel performance in the spotlight

In a collaboration involving Forest Growers Research (FGR), Timberlands, and contractor H.A. Fear, Scion used seaweed[1]based hydrogels in a mechanised planting trial using the ‘M-Planter’. This machine integrates a planting head with an excavator-based carrier for precision forestry.

The initial trial, conducted as part of FGR’s Precision Silviculture Programme, took place in late March 2022 in Tarawera Forest, where conditions in early autumn make it a demanding establishment environment. A subsequent trial in December 2022, conducted in partnership with Rayonier-Matariki Forests, aimed to assess hydrogel performance under drier summer conditions.

Four treatments were applied to container-grown seedlings: a dry control (representing standard practice), root zone water application, surface hydrogel application, and root zone hydrogel application. Three and 12 months after planting, measurements of plant health and size, including height and groundline diameter, were recorded.

Dr Carol Rolando, a Scion senior scientist specialising in forest establishment, says unseasonably wet weather during both trials hindered a comprehensive evaluation.

The trials showed minor positive effects on early growth and there was a slight trend toward increased survival when using hydrogels. The results reflect the unusually wet weather, with 270mm of rainfall over six weeks post-planting, rather than any shortcomings of the hydrogel itself.

“We’ve observed, both in New Zealand and worldwide literature, that hydrogels have demonstrated the potential to significantly enhance tree survival and growth.”

She says despite the initial outcomes, the trials yielded valuable insights, including improved knowledge of the M-Planter’s performance in wet conditions and clay soils, as well as the mechanical application of hydrogels during planting.

Extending the planting window carries numerous advantages for forest owners. These include better use of limited high-quality labour, reduced pressure stemming from tight planting schedules, and optimised site usage by enabling more areas to be replanted rather than deferred to the following year.

Dr John Moore, research and development manager at Timberlands, underscores the role of climate change in this context, particularly on pumice soils where more frequent and severe droughts could potentially compress the planting window.

“While current survival rates are acceptable, hydrogels could offer a buffer and added protection during periods of severe and frequent drought, particularly during a seedling’s initial year.”

Moore says even small changes observed in survival and early growth can have significant implications when planting eight million trees per season.

“The value of early growth gains extends to helping seedlings overcome competition from weeds, ultimately translating to greater performance in later rotation crops.”

The journey now leads to Scion’s nursery, where more research trials will be conducted. The controlled trial will compare the effects of seaweed-based hydrogels with synthetic counterparts on Pinus radiata containerised seedlings over two years, scrutinising factors such as placement, quantity, and application timing.

Hydrogels can seamlessly become part of the process in containerised tree stocks, where each seedling already benefits from a “packed lunch” in the form of a rich and fertile planting medium within each root plug - Dr John Moore

From manual to mechanised

With increased realisation of the benefits offered by integrated forestry, there is a gradual shift from manual and semi[1]mechanised to fully mechanised planting machines. But for the introduction of technology at this level to be economically viable, it needs to offer more than just planting solutions.

The trials in Tarawera Forest and Rayonier-Matariki Forests mark the beginning of a comprehensive assessment under FGR’s Precision Silviculture Programme.

Programme manager Claire Stewart says extending the planting season is crucial to maximising planting machine utilisation, enhancing the overall cost-effectiveness of mechanised operations.

“The New Zealand plantation forest industry heavily relies on manual labour for silviculture tasks, including planting, pruning, and thinning. Labour shortages pose a significant challenge, and mechanisation is a potential solution.”

She says machines like the M-Planter have been equipped with features like a ripper for deep soil preparation, making them suitable for land preparation activities and planting. Beyond the application of hydrogels, fertilisers, growth hormones, or rooting agents could also be considered. These machines could also be multi-use equipped with herbicide, insecticide, or pesticide spray systems.

Timberlands, a participant in the Tarawera Forest trial, identifies three key benefits of adopting hydrogels and mechanised planting systems: enhanced capital utilisation, extended planting seasons, and increased resilience against climate change.

Currently, Timberlands uses mechanical planting for 120ha. Most of the 7000ha annual programme still relies on manual planting methods. This poses a challenge of integrating hydrogels into various planting stocks, but also an opportunity for innovation.

Moore says containerised stock in nurseries is a logical starting point for hydrogel integration.

“Hydrogels can seamlessly become part of the process in containerised tree stocks, where each seedling already benefits from a ‘packed lunch’ in the form of a rich and fertile planting medium within each root plug.

“The trial has helped envision a future where hydrogels could be effectively introduced to forestry practices, acting as a nurturing boost for tree stock, minimising planting stress, and fostering rapid and robust early growth.”

Two parallel streams of work

The nanocellulose extracted from AgriSea’s seaweed waste serves a dual purpose. While it is purified for use in cosmetics and wound care, it can be used in its raw form to support plant establishment.

The Precision Silviculture Programme trials aim to understand the potential impact of hydrogels on growth and increased survival rates. Ongoing laboratory work at Scion is also delving into the underlying science behind it.

New Zealand’s native seaweed, Ecklonia radiata, boasts a wealth of minerals, trace elements, and naturally occurring antibodies.

In the laboratory, Hill says numerous theories are being explored including whether beneficial microorganisms pass through the extraction process and into the hydrogel.

They’re also studying how hydrogels affect microorganisms in the soil. This interaction plays a pivotal role in influencing how plants absorb nutrients and stay healthy.

Hill says by employing hydrogels as a carrier for beneficial microorganisms or as a medium to support microbial activity, they aim to bolster plant resilience and health.

In the realm of agriculture and plant growth, the choice between nanocellulose and petroleum-based hydrogels is becoming more important with the former offering a sustainable and environmentally friendly solution, unlike their petroleum-based counterparts.

Nanocellulose hydrogels lack toxic components, naturally biodegrade (unlike petroleum-based alternatives that can persist in the soil for years), and carry no risk of dehydrating plants, a concern associated with certain hydrogels.

“With its compatibility with plant roots and its potential to regulate water flow, seaweed-based nanocellulose emerges as a promising and environmentally sound choice for enhancing soil quality and fostering healthier plant growth.”