Fostering creativity in young minds

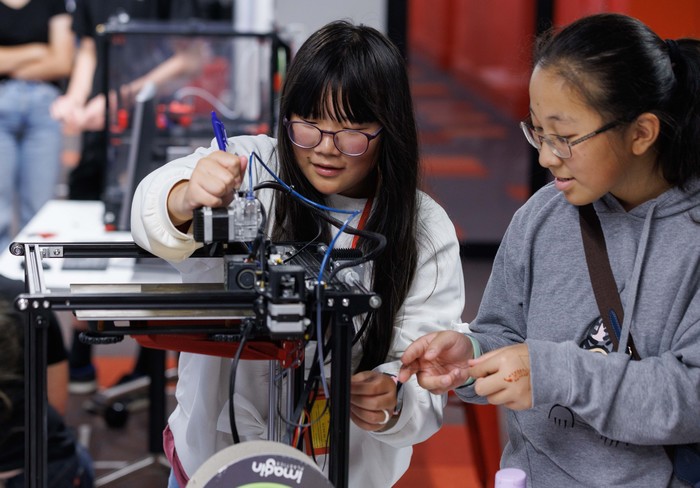

Enthusiastic tamariki gathered around the 3D printers at Te Aka Mauri to learn about the world of 3D printing and Morph, a new flexible 4D printing filament developed at Scion and now commercially available through Imagin Plastics.

A group of Rotorua kids returned to the classroom during the April school holidays to work alongside the Scion team behind the innovative technology, with the opportunity to create something of their own.

Held at Te Aka Mauri l Rotorua Library, the sold-out event saw 25 intermediate and high school students learn the ins and outs of 3D printing during a three-hour interactive workshop. The workshop was the official launch of the new filament.

Scion scientist Dr Angelique Greene says launching Morph to a group of school-aged kids wasn’t coincidental.

“At this age, kids readily absorb information and have the impressive ability to develop more imaginative designs.”

Morph is believed to be the only flexible filament of its kind globally. Its thermochromic properties give the filament its fourth dimension, changing colour when it senses a temperature shift.

During the workshop, kids learnt how to set up 3D printers, how to build 3D models, how to slice those 3D models, what G-code is, and how to initiate printing. Students were also given the opportunity to show off their design skills during a two-week competition using the free 3D CAD tool, Tinkercad.

Greene says young people show us what is possible with this more artistic filament, producing designs that we couldn’t even imagine.

“The true potential of Morph is in the hands of whoever holds it.”

Morph is the result of another successful research collaboration between New Zealand’s leading filament manufacturer Imagin Plastics and Scion.

Imagin Plastics sales and technical manager Ben Blakley says Morph continues a long-standing relationship that began with the development of a wood-filled PLA 3D printing filament in 2018.

“Supporting Scion in the community education space adds another string to Imagin Plastic’s bow, and the Morph team should be proud of the educational impact they’ve made in their community and the steppingstone it could create.”

During the interactive workshop, creative juices flowed as a squid with wings, an alien tower, and tumbling doughnuts started to take shape within moments on computer screens.

Greene says the workshop was about giving back to the community and providing young people with an opportunity to interact with this new filament and meet the people working in science fields they never would have thought existed.

“If these kids weren’t interested in STEM subjects before, they might be interested in it now.”

Scion mechanical engineer Rob Whitton adds that the goal is to create awareness, so when people drive past the Scion sign, they’re familiar with some of the work.

“It’s not all test tubes and lab coats (although there’s plenty of that too), but it’s developing products and innovation, and technology is a big part of that.

“3D printing will be a part of most people’s lives in one way or another in the future, already infiltrating the education sector and commercial industry. In the coming years, 3D printers will be used by the general population, not just by those who like to tinker.”