Growing New Zealand’s bioeconomy

14 March 2019

Using sustainable and renewable biobased products seems to be an obvious way to preserve precious resources and reduce carbon dioxide emissions. Barriers to introduction are slowing their uptake.

Participants from industry, universities, Scion and the German Institute for Bioplastics and Biocomposites (IfBB) workshopped some of the key challenges around wider adoption of biobased products at Scion on February 14. The Bio2AN event was organised by Scion (Rotorua) and the IfBB.

Florian Graichen, co-organiser and Science Leader for Manufacturing and Bioproducts at Scion, said the ‘sold-out’ event met its aims of fostering synergies between circular bioeconomy research and industry in Germany and New Zealand.

“People were particularly engaged in the workshops on policy and industry,” said Florian.

“We provided our perspective on the introduction and uptake of biobased products that Scion has developed. These include products such as fruit labels, biodegradable clips for vineyards, and fish boxes made from polylactide foam. And small to medium enterprises such as Vaude from Germany provided theirs.”

Some of the key challenges to adopting biobased products included:

- Lack of a bioeconomy strategy in New Zealand. (In contrast, Germany and the EU have structured bioeconomy strategies supported by government initiatives.)

- The natural variation in feedstocks from renewable resources

- Finding information about which bioplastic is the most suitable for the application

- Finding suppliers able to supply at scale, and at a reasonable price

- The absence of standards or regulation defining “sustainable”

- Communicating the sustainability story to customers

“These challenges are not new to any one working in this area,” says Florian.

“At Scion, we are working on practical solutions to these with local and overseas manufacturers. One example of a product developed at Scion that was recently launched onto the market is a wood-bioplastic 3D printing filament produced by New Zealand company Imagin. That product is now an NZ Plastics Industry Design Award finalist.”

The workshop outcomes will be made available through the IfBB in the coming weeks. Scion and the IfBB hope to work together to develop cross-organisational research and development programmes to address the challenges identified.

Bio2AN was a travelling conference. Events were also held in Australia at the University of Southern Queensland (Brisbane) and Deakin University (Geelong). The Bio2AN project was supported by the German Ministry of Education and Research. IfBB presenters included researchers from Hochschule Hannover, Technische Universität Braunschweig, Fraunhofer WKI and Vaude.

Contact Florian Graichen for more information.

Presentations from Bio2AN @ Scion are available online

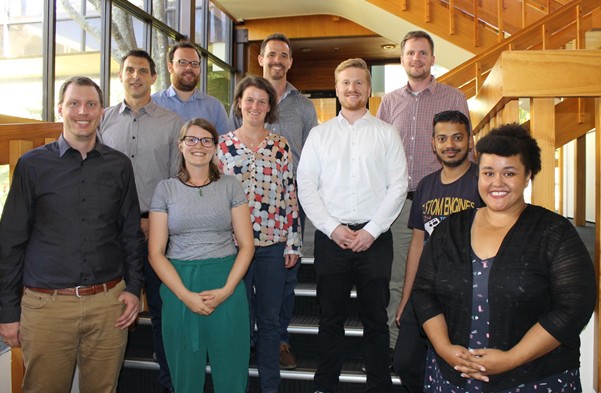

The organisers, left to right: René Bethmann (Vaude), Florian Graichen (Scion), Sebastian Spierling (IfBB), Helena Quilter (Scion), Carmen Arndt (IfBB), Marco Neudecker (IfBB), Julian Rickert (TUBS), Ole Hansen (Fraunhofer WKI), Venkateshwaran Venkatachalam (IfBB), Angelique Greene (Scion).