Timber Engineering Laboratory stands the test of time

5 January 2023

For over 70 years, Scion’s Timber Engineering Laboratory has been trusted to deliver materials, product, technology innovation and performance testing for the construction industry. The work has provided the platform for the New Zealand timber industry and has opened the way for radiata pine to be exported for overseas use.

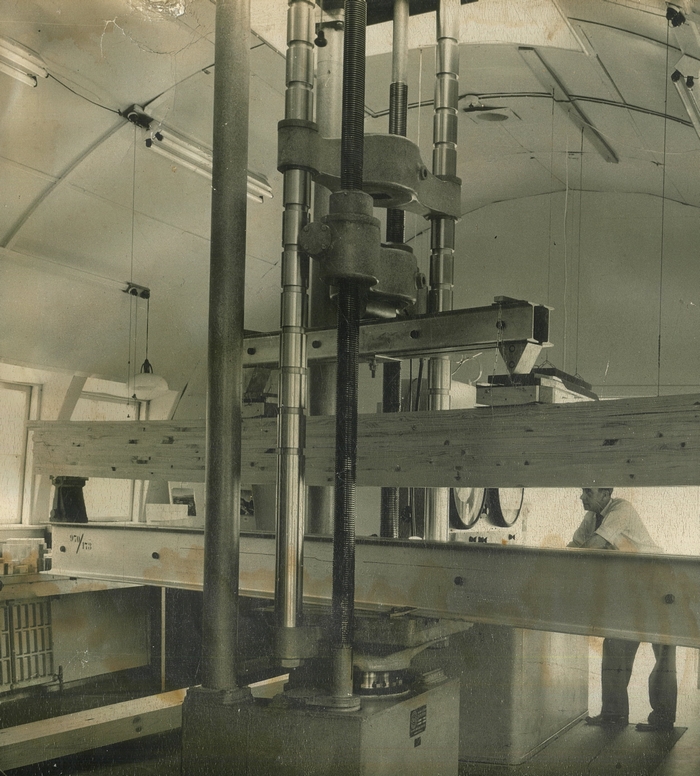

The original laboratory was in one of the ex-Army Quonset huts with the roof lifted to fit the test machine. The Baldwin test machine, purchased in 1955, still does the heavy lifting for the timber engineering lab - albeit with a control system upgrade to computer control.

Before a timber product or fastening system can be used in construction in New Zealand it is likely to have been tested here first. Scion’s timber engineering staff have been a trusted source of technical information for New Zealand timber and construction standards. Expertise has been provided on the design of engineered timber structures, domestic housing, grading methods, glulam, finger-jointed timber, fibre cement, plywood, structural jointing and fastening systems.

The primary outcome for Scion’s timber engineering clients is that our independent test results enable them to enter the market with high confidence.

Mechanical testing of timber properties in New Zealand began in the 1930s with most of the testing taking place at the University of Canterbury and Auckland University. Testing began in Rotorua in the early 1950s.

By and large, the specialised testing machinery in use today has stood the test of time. An Avery-Denison impact tester built in Leeds England has the words ‘War Issue’ stamped on it indicating that the machine even pre-dates the establishment of the Forest Experiment Station in otorua 75 years ago.

Scion’s role in verifying high-performing wood products helps ease the way for wood construction, which ultimately aligns with New Zealand’s Wood First policies.